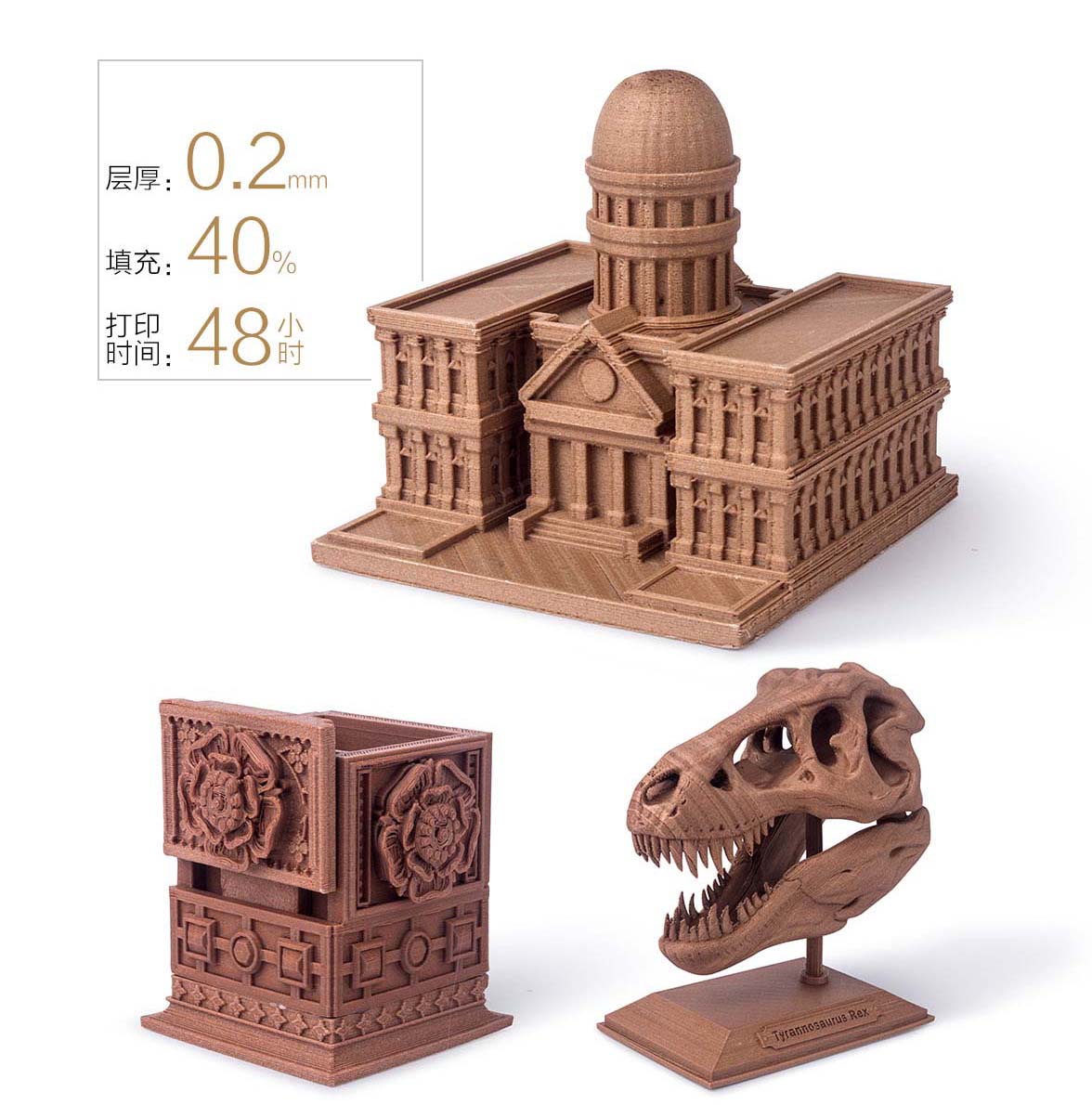

XYD-Wood and Bamboo 3D consumable, it is Low-carbon and environmental. It is mainly made by poly lactic acid, natural wood powder and bamboo. It diffuses fragrancy of wood and bamboo during the printing process .Its products contains the feeling of wood, they are able to be polished, chased, printed and drilled, but as their base material`s low shrinking percentage, their strength and anti-impact properties are relatively weak. If you love art, you will like them, because they bring you fun and special effect of the whole post processing.

You have to make sure whether your printers are suitable for this material(please call the printer maker). In high-temperature environment for long time, the wood and bamboo would turn into carbon, it will block nozzles, so you should clean the nozzles. We advise users use nozzles whose diameter is from 0.4mm to 0.6mm, the consumable should not be stayed in high-temperature environment after printing.

Printing temperature

Printing temperature Product Features

Product Features Product specifications

Product specifications Packing

Packing

| Physical properties of materials | Testing standards | ABS | Flame retardant ABS | HIPS | FLEX | MAX | WOOD | Bamboo | PLA | WOOD | Bamboo | PLA |

| Specific Gravity | D792 | 1.05 | 1.17 | 1.05 | 1.2 | 1.27 | 1.05~1.18 | 1.0~1.18 | 1.24 | 1.05~1.18 | 1.0~1.18 | 1.24 |

|

Heat change temperature H.D.T Annealed(85℃,8hr) Unannedaled |

1/4",120℃、hr |

99(210) 88(190) |

85(185) 76(169) |

90 | / | 70(0.455Mpa(66psi) | 65 | 65 | 60 | 65 | 65 | 60 |

| MFR(200°C,g/10min) | 200℃,5kg | 1.8 | 4.8 | 8 | 12.1 | 20(250℃2.16KG) | 8~18 | 8~18 | 5~12 | 8~18 | 8~18 | 5~12 |

| Bending strength (MPa)Tensile Strength@Break,psi | ASTM D790 | 820(11660) | 640(kg/c㎡) | D638/450 | / | Mpa(kgf/cm2)71(720) | 5500 | 5500 | 7770 | 5500 | 5500 | 7770 |

| Tensile Elongation,% | ASTM D638 | 20 | 15 | 40 | >400 | 4.5 | 5.5 | 5 | 6 | 5.5 | 5 | 6 |

| Notched lzod lmpact,ft-lb/in(J/m) | ASTM D256 |

18(3.3) 20(3.7) |

3.8 | 11 | 85 | 85 | 0.06 | 0.06 | 0.1(16) | 0.06 | 0.06 | 0.1(16) |

| Printing temperature | ℃ | 220℃-260℃ | 220℃-260℃ | 210℃-260℃ | 195℃-245℃ | 230℃-260℃ | 190℃-230℃ | 190℃-230℃ | 190℃-230℃ | 190℃-230℃ | 190℃-230℃ | 190℃-230℃ |

Mr Yang

Mobile site